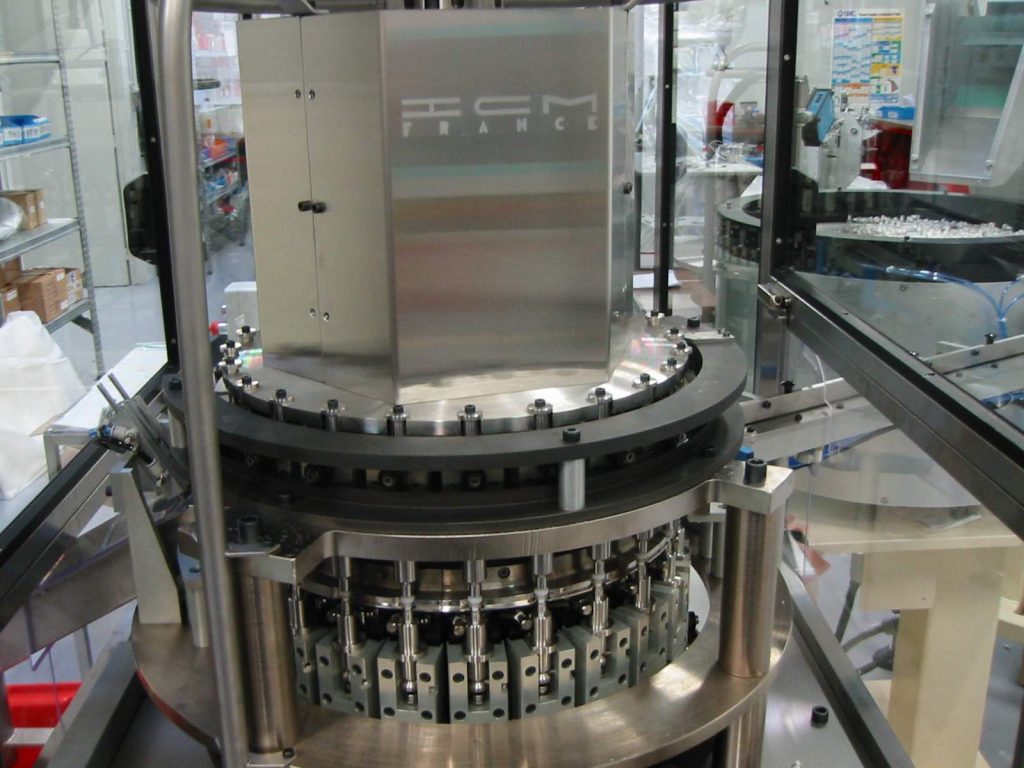

Improvements and expansion of continuous motion assembly machine has had a major impact on the productivity of manufacturing industry since the Industrial Revolution. The impact has been both direct and indirect.

The direct impact consists of increased labor productivity due to faster, more accurate, and more mechanized machines, and increased capital productivity due to higher operating rates, greater reliability, and higher utilization rates.

The indirect impact is because the use of new or improved machine tools has necessitated or facilitated organizational changes affecting labor, capital, raw materials and energy.

In this article we are going to know in detail the impact of industrial machinery from its birth to our times, without neglecting its evolution and its main role in an increasingly connected industry.

What is industrial machinery?

Industrial machinery is defined as the machines and equipment used by a manufacturer in a manufacturing plant. Another concept of machinery is any mechanical, electrical or electronic device designed and used to perform some function and produce a certain product.

Any add-on or accessory necessary for the basic unit to perform its intended function is considered part of the machinery. The term also includes all devices used or necessary to control, regulate or operate a continuous motion assembly machine, provided that such devices are connected with or are an integral part of the machine and are used to control, regulate or operate the machine.

Dies, dies, tools and other devices necessary for the operation or used in conjunction with the operation of what would generally be considered machinery are also considered «industrial machinery.»

Machinery does not include buildings designed to house machinery. Similarly, heating and air conditioning systems are not considered industrial machinery and equipment unless the sole justification for their installation is to meet the requirements of the production process.

What is industrial machinery used for?

The design, manufacture and use of professional industrial machinery has changed significantly over the past 50 years with new designs, simulations and visualizations, as well as automation that improves product quality, saves time, reduces costs and increases throughput.

Another big change in industrial machinery is that it is now designed and produced all over the world. For example, traditional manufacturing centers such as the United States, Germany and Japan are now in stiff competition with South Korea, India and the Philippines.

Ultimately, industrial machines are used in agriculture, on assembly lines, by industrial robots, and in oil refineries, packaging and labeling, paper mills, sawmills and foundries, among many other uses.

The importance of industrial machinery

In today’s modern world, machines play a vital role in ensuring the speed of a number of activities. In most industries, you will find that machinery has completely replaced human labor. The industrial field has faced tremendous development and there is a lot of dependence on technology.

With the massive advancement of technology, there is less need for manual labor. According to statistics, the desire for manual labor has decreased significantly. Machines are invading these industries, pushing humans aside.

It is important to note that the purchase of machines can be an effective way to innovate in the business, provided that the entrepreneur does some advance planning. This means that, in addition to the continuous motion assembly machine, it is necessary to evaluate the available area in the factory and the money that will be spent on equipment maintenance.